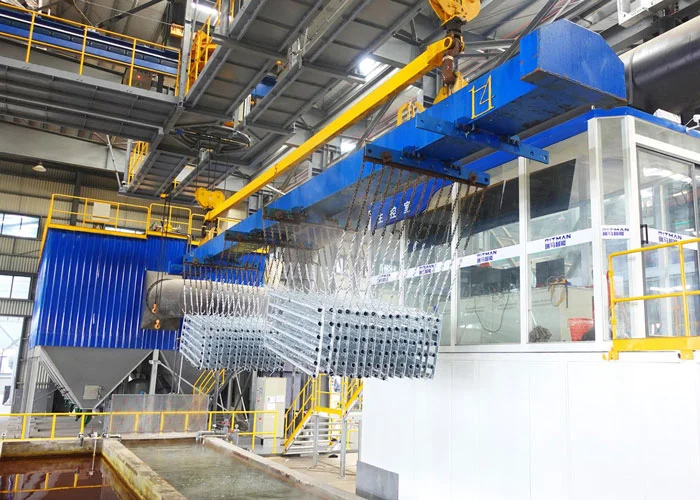

Batch hot dip galvanizing line

Batch hot dip galvanizing line

- China's largest galvanizing equipment manufacturer

- Host of the International Hot Dip Galvanizing Conference

- Fast turnkey project, Environmental protection

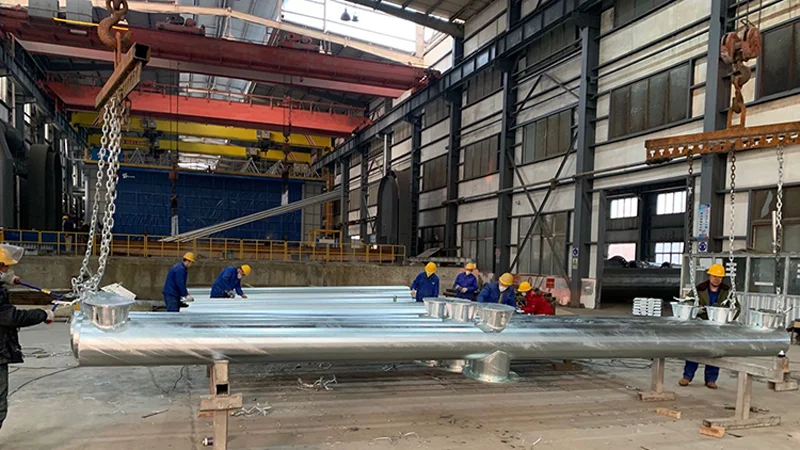

Can be used for almost all steel parts, including scaffolding, light poles, pipes, monopole towers, angles, structural parts, roof members, highway fences,white goods, containers

Turnkey Project

Turnkey galvanizing lines are desgned and produced accordng to costumers request. Desgn, manufacture and setup. Hgh performance. On-tme delvery.

FEATURE

Why we’re different

Xuzhou RITMAN Equipment Co., Ltd. is a metal machine manufacturer and manufactures machines to make the best of galvanizing.

- Our machinery and equipment design includes our expertise for galvanizing.

- Our manufacturing capabilities makes you deal with big projects in short time periods without losing quality.

- You immediately start using our machinery in your production. No time is lost.

Our Awards

0+

Our Work

0+

Member

0+

OUR SERVICES

What we do

Cases

Customer Reference Case

The Steps Of The Hot-dip Galvanizing Process

Download center

Hot-dip Galvanizing Line Brochure

Brochures and further information about our processing lines, products, equipment and lifetime services for our hot-dip galvanizing lines