Cases

FEATURED PROJECT

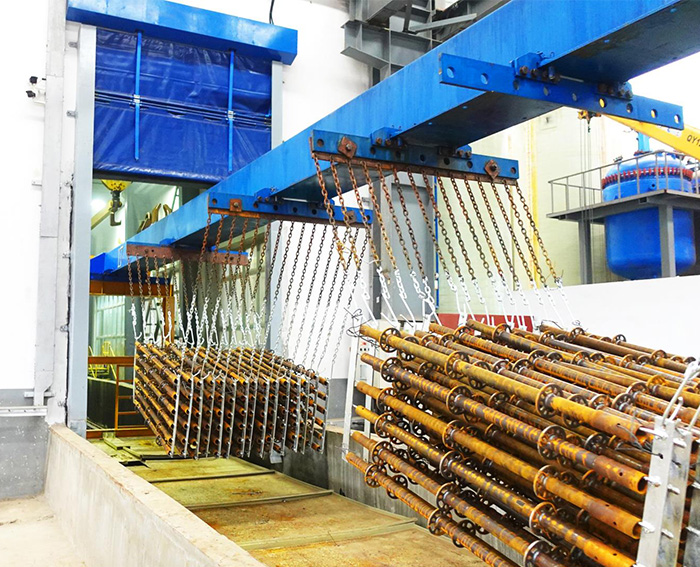

Zhejiang Project

- Project: Zhejiang Project

- Contractor: RITMAN

- Kettle size: 15.5m*2m*3m

- Output: 100,000 MT per year

The continuous galvanizing line is a specialized equipment for the production of galvanized steel coils. The production line adopts a continuous operation mode and has a high degree of automation, making it suitable for mass production. With an annual output of 300,000 tons, the production line includes a decoiler, a welding machine, a pre-treatment device, a cleaning unit, a drying furnace, and a galvanizing furnace.

The pre-treatment device includes a degreasing tank, a pickling tank, and a washing tank. The cleaning unit consists of a brush roller, a water washing tank, and a blowing device. The drying furnace is composed of a furnace body, a heating system, and an exhaust system. The galvanizing furnace is composed of a furnace body, a zinc pot, a heating system, and a cooling unit.

During the operation, the steel strip enters the decoiler through the feed port and is then welded into a continuous strip. The continuous strip then passes through the pre-treatment device, cleaning unit, and drying furnace to remove grease, rust and other impurities on the surface. The strip then enters the hot-dip galvanizing furnace, where it is completely immersed in the zinc pot, taken out, and then cooled. Finally, the coated steel strip is coiled by the coiling machine. The production line runs stably, is highly automated, and has excellent product quality.

| Zhejiang Project: | |

| Kettle size: | 15.5m*2m*3m |

| Output: | 100,000 MT per year |