Cases

FEATURED PROJECT

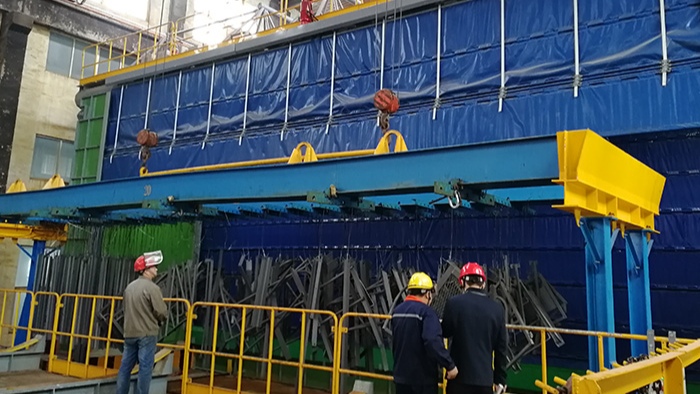

Haiyang Yongfeng:Modernizing Hot-dip Galvanizing Production Line

- Project: Haiyang Yongfeng

- Contractor: RITMAN

- Kettle size: 13.8m*2.2m*3.5m

- Output: 80,000 MT per year

A steel company in the United States was using a traditional hot-dip galvanizing production line that was prone to accidents and caused environmental pollution. To address these issues, the company decided to modernize its production line.

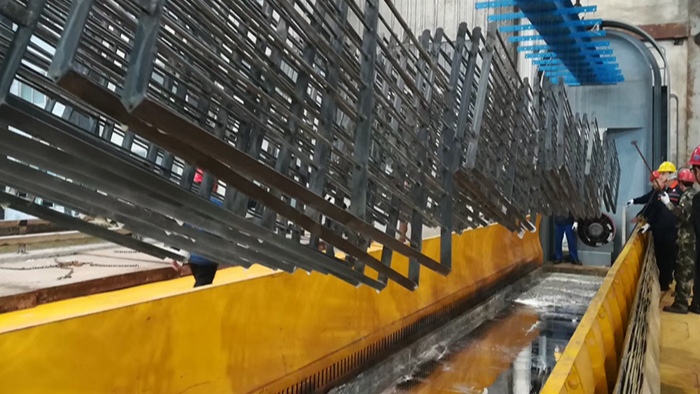

This modernization included the install of a dual-chamber furnace, which greatly reduced energy consumption and improved product quality. The company also updated its zinc bath control system, which improved the accuracy of product coating and reduced the amount of zinc used. Additionally, the company implemented an abrasive blasting system to clean the product surfaces before galvanizing, which resulted in better adhesion of the zinc layer.

After the modernization, the company saw a decrease in the number of accidents and a significant reduction in harmful waste generated by the production process. In addition, the product quality was greatly improved, which increased customer satisfaction and enhanced the company's reputation in the market.

| Haiyang Yongfeng: | |

| Kettle size: | 13.8m*2.2m*3.5m |

| Output: | 80,000 MT per year |