Cases

FEATURED PROJECT

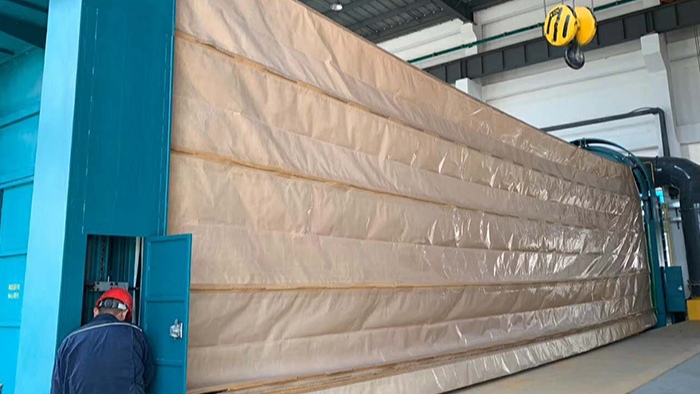

Anhui Hongyuan:Revitalizing Hot-dip Galvanizing Production Line

- Project: Anhui Hongyuan

- Contractor: RITMAN

- Kettle size: 12.5m*2.4m*3.4m

- Output: 100,000 MT per year

A steel company in Korea invested in a hot-dip galvanizing production line for anticorrosion purposes. However, as product requirements became more demanding, the company realized that the traditional production line could not keep up with the pace.

To address these challenges, the company upgraded their hot-dip galvanizing line. First, they installed a high-speed centrifugal dryer, which greatly reduced product drying time and increased production efficiency. Second, the company introduced a gas-fired chamber furnace and updated the fluxing process to reduce energy consumption and environmental pollution. Finally, the company implemented an automated packing and handling system, which reduced labor costs and minimized product damage during shipping.

After these improvements, the company saw a significant increase in productivity and profit margins. The final product quality also improved, leading to higher levels of customer satisfaction. This successful transformation of the hot-dip galvanizing line has allowed the company to better meet market demand, strengthened its position in the industry, and contributed to the sustainable development of the enterprise.

| Anhui Hongyuan: | |

| Kettle size: | 12.5m*2.4m*3.4m |

| Output: | 100,000 MT per year |